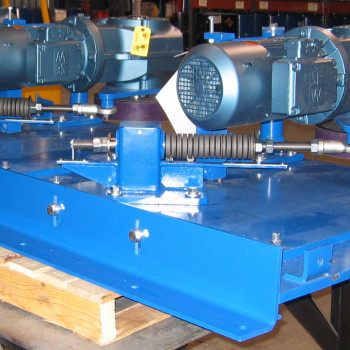

Conveyor Subassemblies

Situation: The conveyor manufacturer needed a domestic supplier to provide complete conveyor subassemblies. The customer was previously purchasing the product overseas, and it was both expensive and time consuming for the product to be imported from Europe. Solution: Conveyor Concepts designed, manufactured and delivered these products in less than three weeks. This saved the

Heavy Duty Conveyor System

Situation: An automotive assembly plant needed a heavy duty conveyor system repaired. The complex system had a wide variety of drive wheels, idler wheels and buffer wheels. The problem was that the conveyor was manufactured in Europe and the replacement parts had significant lead times and costs. The customer needed a...read more »

Polyurethane V Roller

Situation: A major pipe manufacturer was experiencing frequent failures and shortened life cycle of polyurethane v rollers used in the processing of pipe. When these failures occurred, manufacturing was interrupted while a new polyurethane v roller was put into place. The customer wanted to minimize or shorten the downtime as significant resources were being applied to the...read more »

Wheel Failure Solved and Downtime Reduced

Situation: Polyurethane wheels used as drives and idlers for conveyor systems were frequently being replaced due to wear issues and chunking out of the wheels. The process of changing the wheels was a two person job which took over an hour per unit. Due to the extended lead times from Europe for OEM replacement parts, the customer...read more »