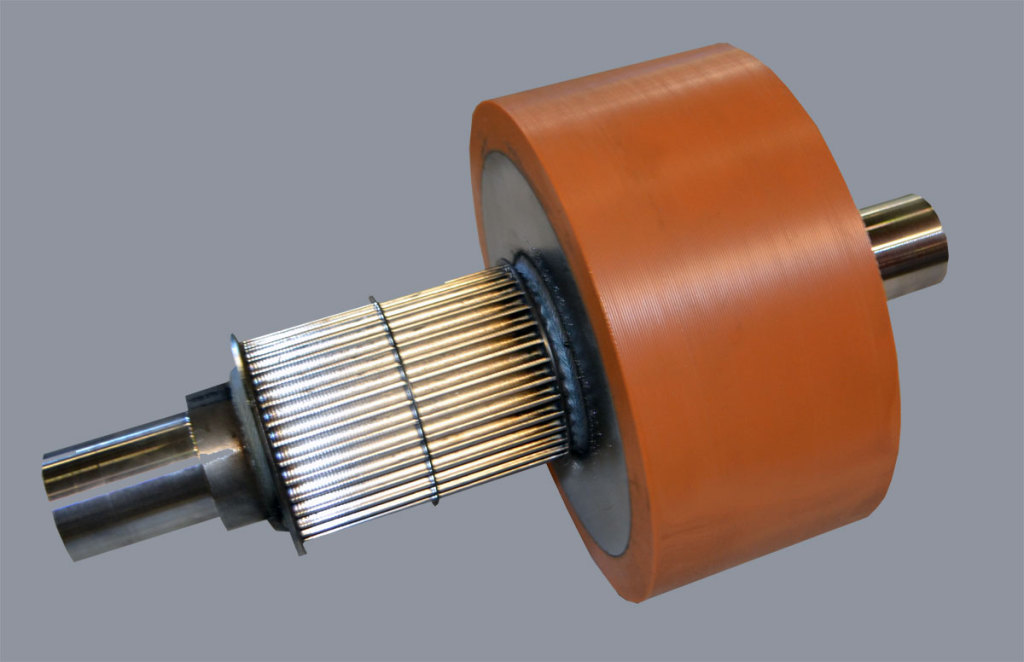

Polyurethanes

If your rollers need extra polyurethane, we can provide a high-quality product that will meet all your specifications and needs.

High speed/high load wheel and roller applications often use special high performance polyurethane treads. NDI and PPDI are most common. An alternative is TODI polyurethane which has significant advantages over the traditional materials. Extensive testing has shown that TODI poly performs comparably to NDI and PPDI, at a significantly lower cost.

When comparing the chemical structures of the ultra-high performance elastomers to those of other polyurethane elastomers, the underlying structure is key to their improved properties. Their structures are rigid, compact and symmetric. The TODI elastomer shares many of the same structural characteristics which suggest it is in the same class as the NDI and PPDI elastomers.

The mechanical properties of all of the NDI, PPDI and TODI polys are similar. These properties includ compression set and rebound. The higher the compression set value of an elastomer, the greater the chance that the tread of a wheel or roller will flat-spot. PPDI elastomers have higher compression set values during dynamometer testing. Rebound is measured by dropping a standard weight onto a specimen from a specified height and measuring the height of the observed rebound. A perfectly elastic material would have a rebound of 100% while a perfectly inelastic material would have a rebound of 0%. All of the aforementioned urethanes have relatively high rebound values.

Dynamic mechanical analysis (DMA) can be used to predict field performance. It is used to measure a material ability to store and dissipate mechanical energy. DMA measurements are based on how much stress is generated in the elastomer when a strain is applied. This stress is out of phase with the applied strain by a phase angle known as delta. Generally the data from DMA is expressed in terms of tan delta. This gives the ratio between the energy lost and the energy stored during a cyclic strain cycle. It is zero for an elastic material and infinite for an inelastic material. Polyurethanes are fairly elastic so tan delta values are generally between 0.01 and 1.0. All of the ultra-high performance polyurethanes have similar, very low values of tan delta.

DMA can be useful in prescreening materials, but dynamometer testing provides more accurate data of the material load-carrying capability at a given speed. The NDI, PPDI and TODI polyurethanes in accelerated failure testing model all failed at similar loads and generated similar amounts of heat when run under identical test conditions. The results of the testing suggest that TODI polyurethanes perform comparably to other high performance polyurethanes in dynamic wheel and roller applications.

In summary it is accurate to say that the TODI material that was tested showed not only similar chemical structure, in side by side dynamometer testing showed equal performance and life cycle. Similar results were also found in DMA testing along with rebound and compression set testing. TODI should be a very acceptable material for demanding wheel, roller and conveyor applications at reduced costs.

At Reaction Industries, a subsidiary of Caster Concepts, the engineering staff can assist you in determining if the TODI polyurethane would be suitable for your demanding dynamic applications. When planning for applications where the wheel material must exceed the traditional parameters input from engineers with extensive knowledge and experience can simplify the specification process and give you years of reliable performance and low maintenance costs.